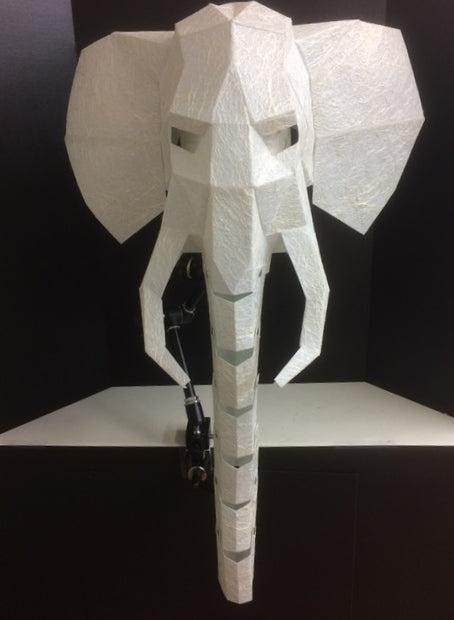

Wonderflex and Fosshape

Filters

8 products

Fosshape 300 Full Meter

Sale price$35.01 CAD

Fosshape 600 Full Meters

Sale price$48.00 CAD

Fosshape 400 Black Full Meter

Sale price$45.00 CAD

WonderFlex Pro Sample

Sale price$4.00 CAD

Wonderflex - Half Sheet

Sale price$50.00 CAD

Wonderflex Pro - Full Sheet

Sale price$90.00 CAD

Wonderflex Pro - half sheet

Sale price$49.50 CAD

Wonderflex Pro - Quarter Sheet

Sale price$28.50 CAD